17 Sep Our Custom Made Capabilities

As a high quality power transmission parts supplier, we have adequate and modern state of the art in-house machines and tooling, with which we are more than capable of manufacturing industrial chains, sprockets, gears, etc.:

Industrial chains – agriculture chain, rubber top chain, stainless steel chain, drop forged chain, U type chain, roller chain, special chain, hollow pin chain, conveyor chain.

Sprockets – stainless steel sprockets, taper bore sprockets, platewheels, and idler sprockets.

Gears – general turning, spur gears, worm gears, bevel gears.

Pulleys – V belt pulleys (including taper lock bush), plain bore timing pulleys, htd plain bore timing pulleys, taper bore timing pulleys, plain bore timing pulleys, htd taper bore timing pulleys, htd timing pulley bars, timing pulley bars.

What started as a small and humble workshop in Hangzhou 20 years ago, gradually developed into today’s fully grown business with comprehensive in-house capabilities of industrial chain manufacturing. Starting with just about 10 employees and a small production workshop, we managed to land our first international customers looking for reliable industrial chain manufacturers in China.

Today, our power transmission parts manufacturing capabilities are spread over 5000 sqm in two manufacturing plants. We are housing modern state of the art machining and tooling assets and between 50 and 100 highly skilled and experienced workers that run all the productions lines.

We especially excel in providing our clients custom made solutions for their machinery. Our expert craftsmen listen to your needs very carefully and design a product in line with your needs and requirements. The design is then turned over to our highly skilled manufacturing team that make your products with great precision and care. Whether industrial chains, sprockets, agricultural chains, gears or rubber top chains, our highly skilled power transmission parts craftsmen can produce any solution with our on-board capabilities.

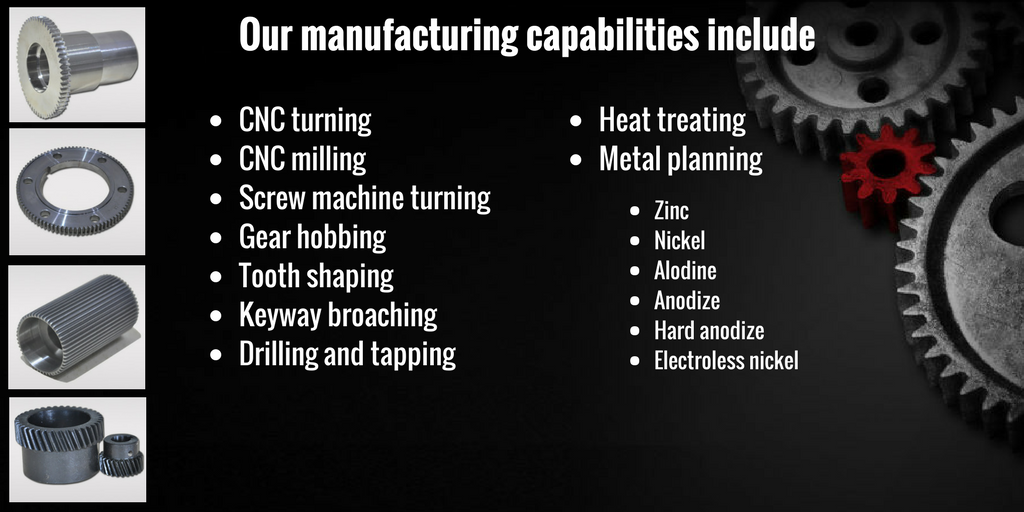

Our custom made manufacturing capabilities

Our power transmission parts manufacturing capabilities include CNC turning, CNC milling, screw machine turning, gear hobbing, tooth shaping, keyway broaching, drilling and tapping, heath treating, and metal planning (zinc, nickel, alodine, anodize, hard anodize, electroless nickel).

Our experienced staff can advise and assist you with designing the right part for you; help you save money with cost effective solutions; keep up with ever changing demands; and improve the overall efficiency.

Simply write us or give us a call to find out. We will make sure to provide you with the best possible solution for your needs. Whether transmission chains, sprockets, conveyor chains, gears, drop forged chains, timing belt pulleys, or agricultural chains.

You can find out more about our power transmission parts here (our products).

Click here to see our product catalogs.