Customized and Black Oxide Spur Gears | Durable and Corrosion-Resistant

SPUR GEAR CUSTOMIZED AND SPUR GEAR BLACK OXIDE

Jinpu Mechanical has more than twenty years of manufacturing experience in making gears, complete with CNC turning, milling, broaching and grinding. We deliver extraordinary capabilities to our valued customer base from metal industry types. From custom cutting to fresh improvements of your new product, we have the required production experience your project requires.

The high quality materials that we use to manufacture our gears include stainless and carbon steel, black oxide coating, and bronze and plastics. We can also finish and heat-treat parts and offer just-in-time delivery services when required.

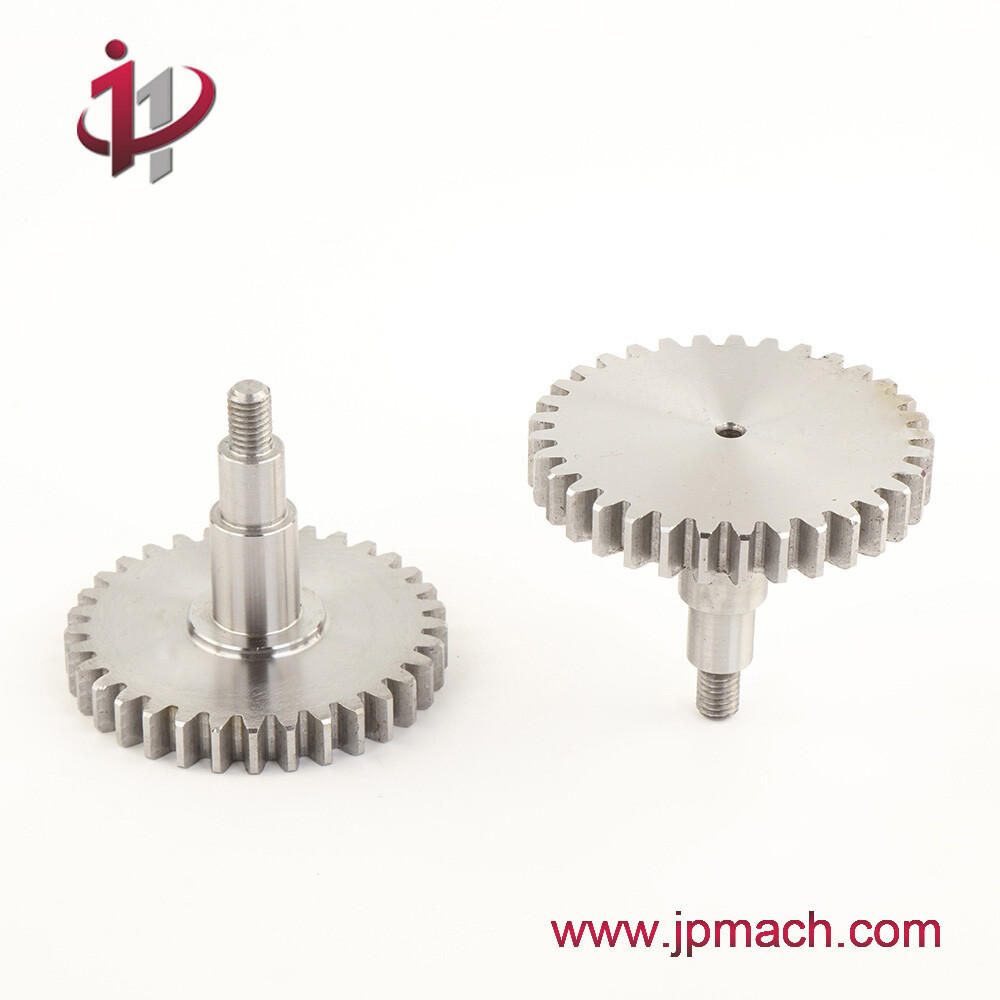

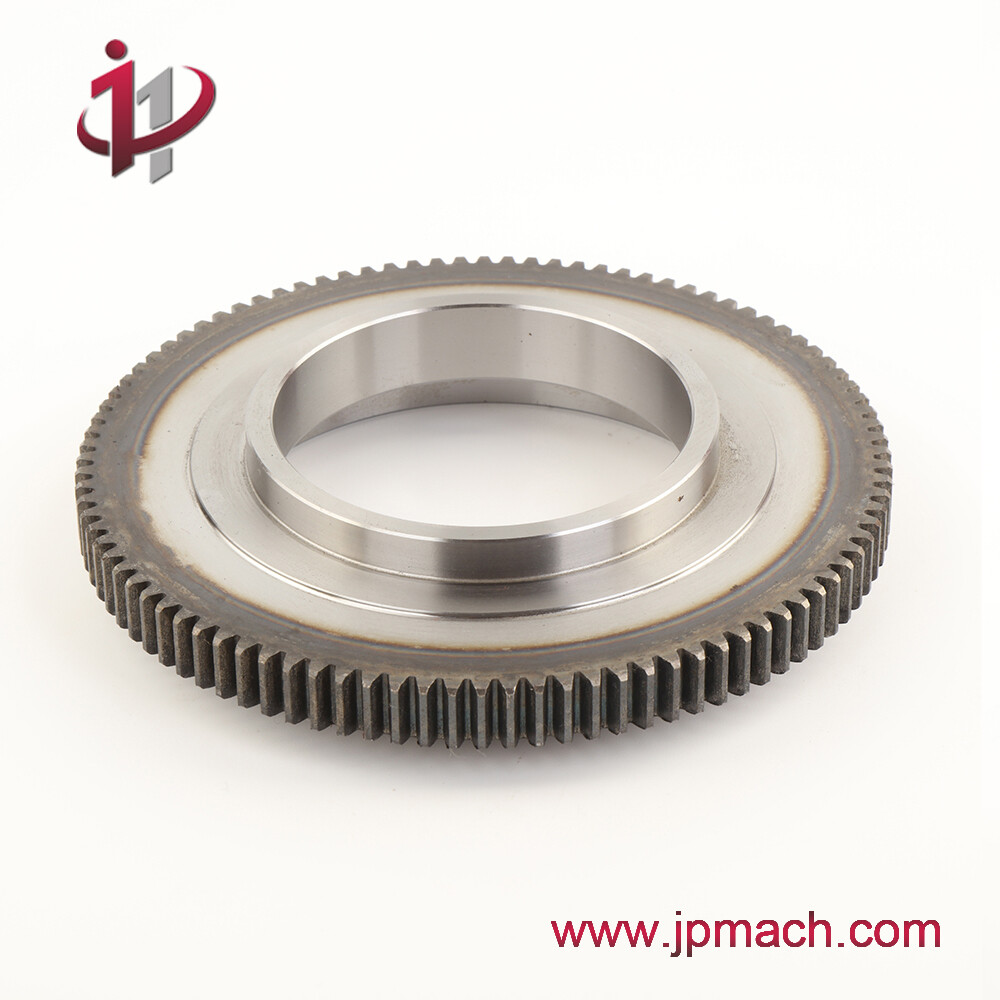

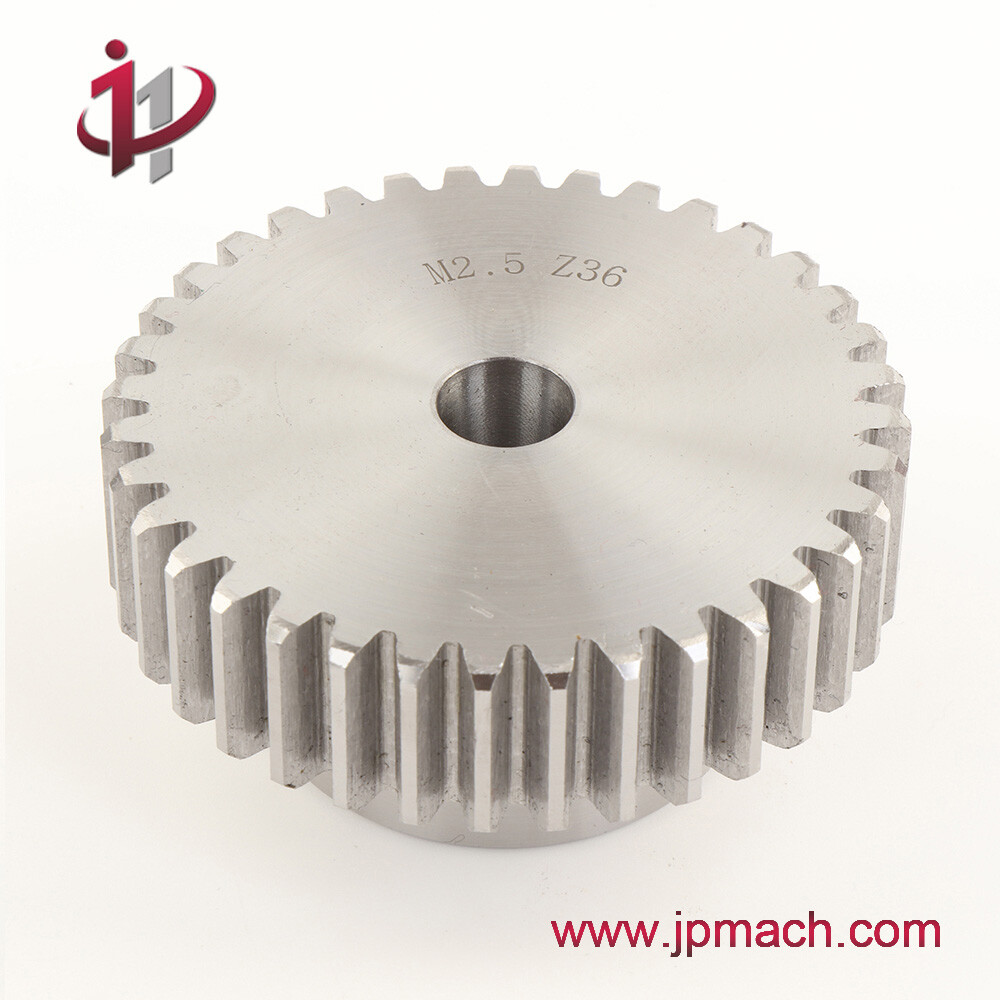

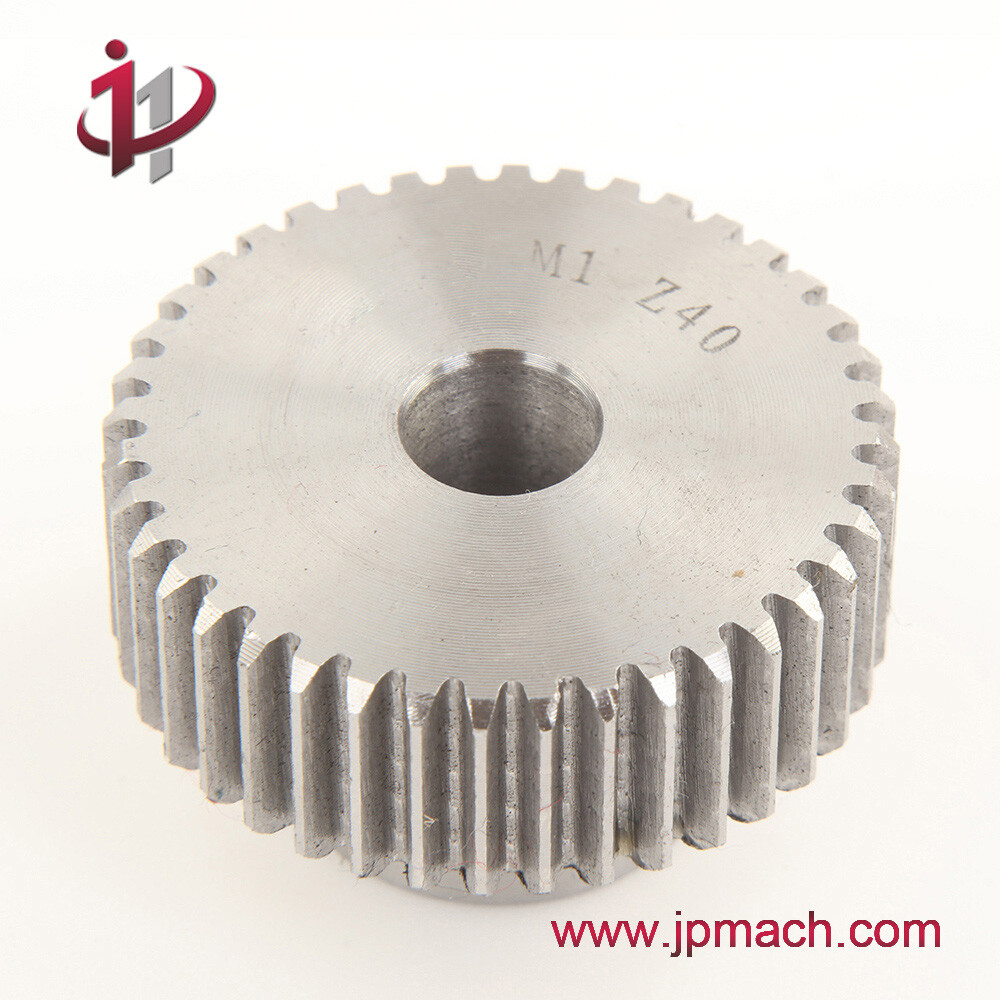

Spur Gears Customized

With over twenty years in the business, we have countless batches of gear production behind us. Some of the most notable are spur gears customized. Designed, manufactured and calibrated for many of our clients. We provide nothing but precise and high quality customized spur gears that match our clients’ specifications and expectations.

There are three main types of spur gears in the spur gear realm. These are rack-and-pinion spur gears, internal tooth spur gears and external tooth spur gears. Spur gears are of course known also by a few other names such as spur gearing, spur wheels, straight cut gears and straight gears to name just a few.

One of the biggest advantages of the spur gears customized is in its low manufacturing cost. This can be achieved thanks to the simple spur gears designs. Customized spur gears are therefore quick and very cheap to produce.

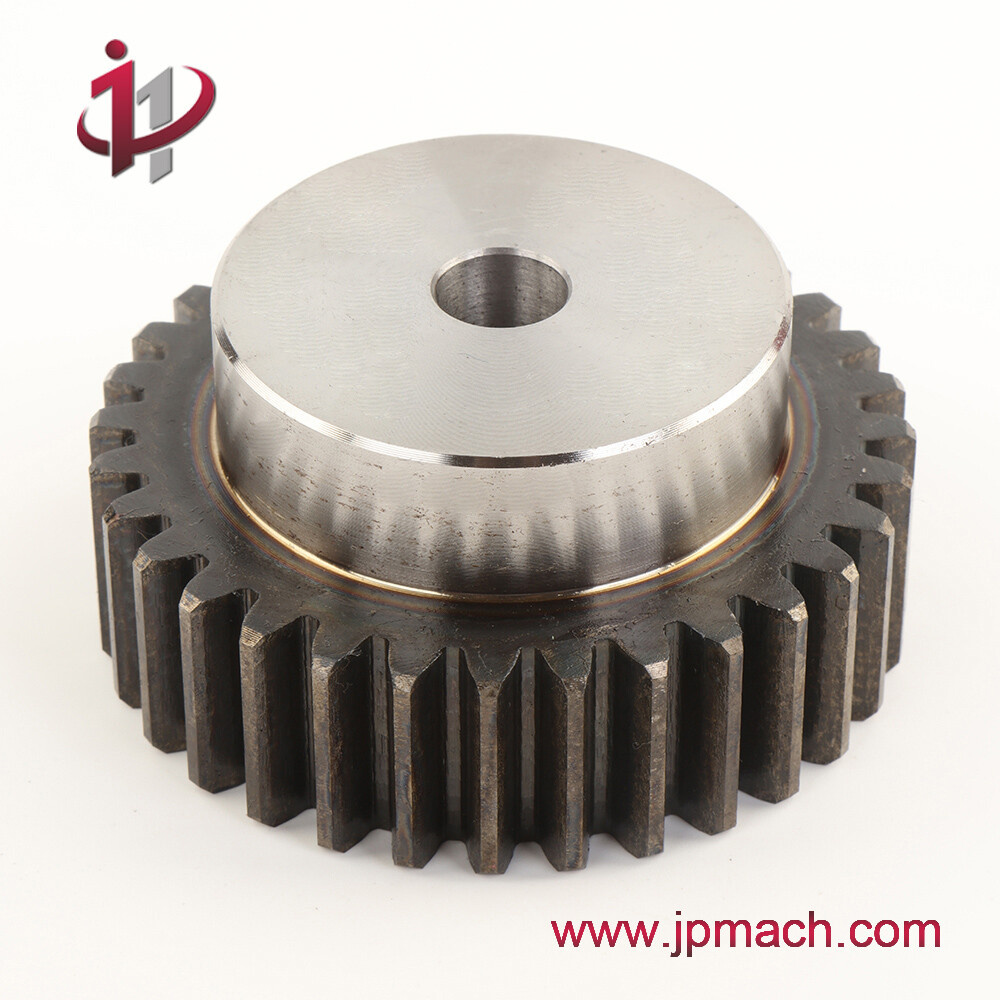

Spur Gear Black Oxide

Besides the spur gears, our factory is quite capable and well established to manufacture spur gear black oxide as well. If you have special needs to protect your spur gears from the ever lingering threat of corrosion, then black oxide coating is the correct solution to meet your needs. Spur gears are covered with black oxide coatings with purpose to protect the gears from rusting. The black oxide coating likewise has a lowered reflectivity and meets optical performance requirements. Compared with spur gears made out of stainless steel, spur gear black oxide offers extra protection from corrosion and significantly reduces the reflectivity of stainless steel.

Below you will find our selection of gears of all types that we currently offer to the market. Contact us directly for any of the gears of interest. Our well trained and experienced English speaking team will especially devote their attention to help you achieve the desired spur gears customized and spur gear black oxide. Whatever the specifications, we will work diligently with you to achieve it.