19 Jun Construction Of The Roller Chain

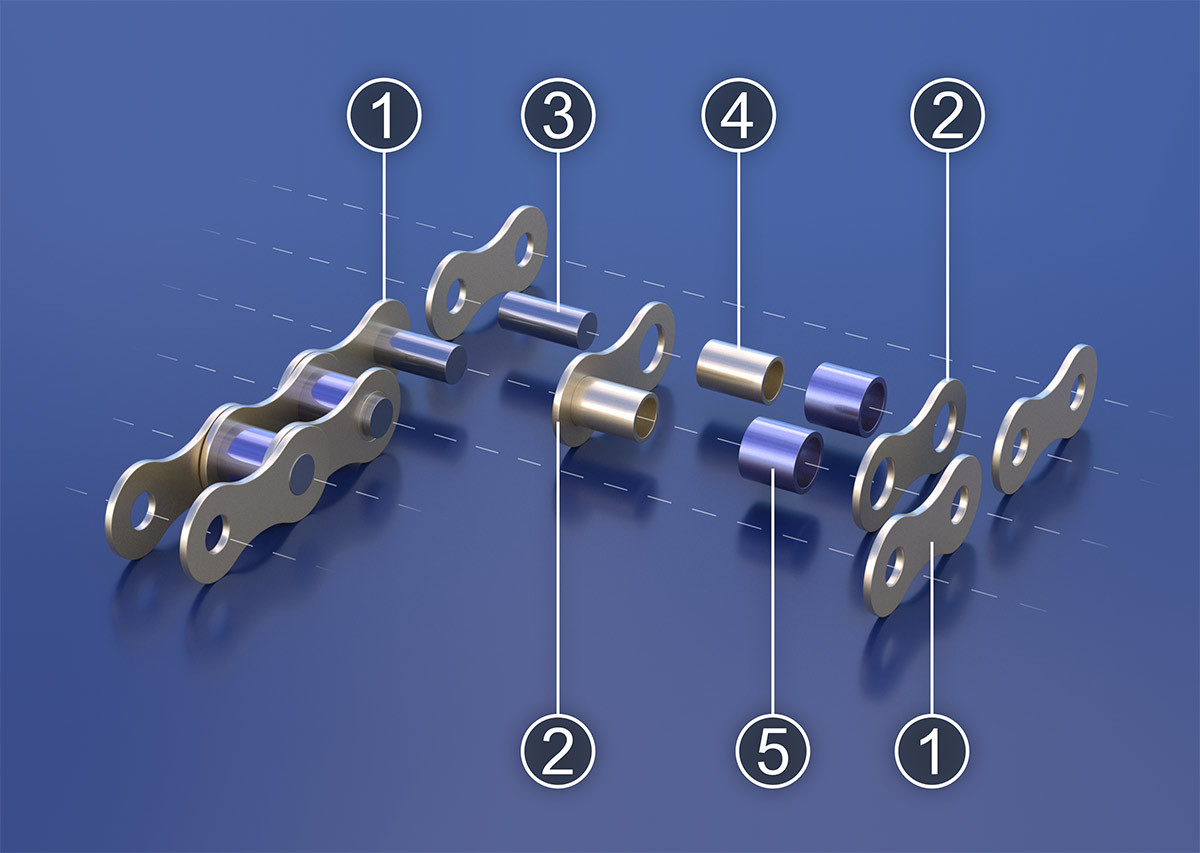

There are really two sorts of connections rotating in the hedge roller chain. The primary kind is internal connections, having two inward plates held together by two sleeves or bushings whereupon pivot two rollers. Internal connections substitute with the second sort, the external connections, comprising of two external plates held together by pins going through the bushings of the inward connections. The “bushingless” roller chain is comparable in task however not in development; rather than independent bushings or sleeves holding the inward plates together, the plate has a tube stamped into it distending from the gap which fills a similar need. This has the benefit of expelling one stage in gathering of the chain.

The roller chain configuration lessens grating contrasted with less difficult plans, bringing about higher productivity and less wear. The first power transmission chain assortments needed rollers and bushings, with both the internal and external plates held by pins which specifically reached the sprocket teeth; anyway this design displayed amazingly quick wear of both the sprocket teeth, and the plates where they rotated on the pins. This issue was somewhat unraveled by the advancement of bushed chains, with the pins holding the external plates going through bushings or sleeves interfacing the internal plates. This dispersed the wear over a more noteworthy zone; anyway the teeth of the sprockets still wore more quickly than is attractive, from the sliding contact against the bushings. The expansion of rollers encompassing the bushing sleeves of the chain and furnished moving contact with the teeth of the sprockets bringing about brilliant protection from wear of the two sprockets and chain too. There is even low grinding, as long as the chain is adequately greased up. Consistent, clean, oil of roller chains is of essential significance for proficient activity and in addition revise tensioning

Related Search-

What is the preparation for chain installation and maintenance?